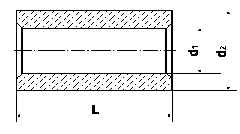

Cutouts with preventers on the common plate are aimed for protection and infrequent manual commutations of alternate current lines with frequency in 50 Hz and voltage in 380 V. They can be used in completing power boxes, compartments, desks and other switchgears.

Mechanical wear-resistance - not less than 10 000 cycles «On / Off».

Commutation wear resistance in alternate current lines with voltage rating and phase factor 0.95 is not less than 500 cycles, when current is 0.5 In for machines with current rating 100 A, 250 A and 400 A.

Switching capacity in alternate current lines with voltage in 1.1 Un and phase factor in 0.95 is not less than 10 cycles «On/Off», when current is 1.5 In for machines with current rating 100 A, 250 A and 400 A.

Un - nominal working voltage

In - nominal working current